AutoCAD (2D & 3D)

Engineering & Prototyping Services

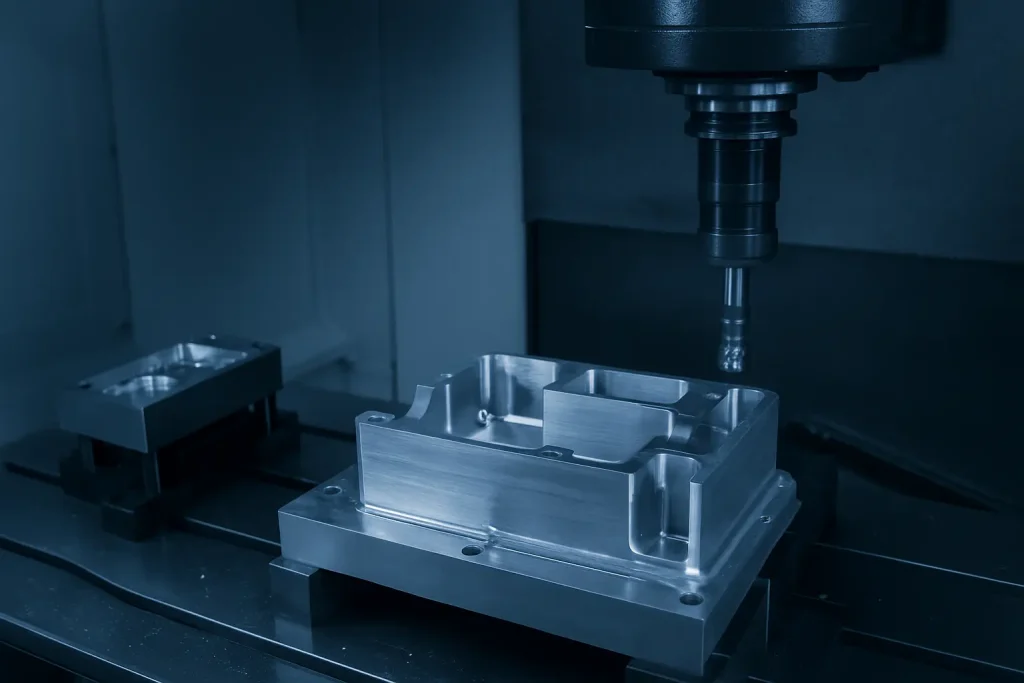

From Concept to Machined RealityAt Paramount Industrial, we don’t just manufacture parts — we engineer precision from the ground up. Our engineering and prototyping services are designed to help customers bring complex ideas to life quickly, accurately, and cost-effectively.

Whether you’re refining a prototype, optimizing for manufacturability, or building a new tooling system, our in-house team supports every stage of the process — from design and CAD/CAM programming to fixture creation, test builds, and pilot production.

Engineering & Prototyping Services

Design. Simulate. Manufacture.Service

Details

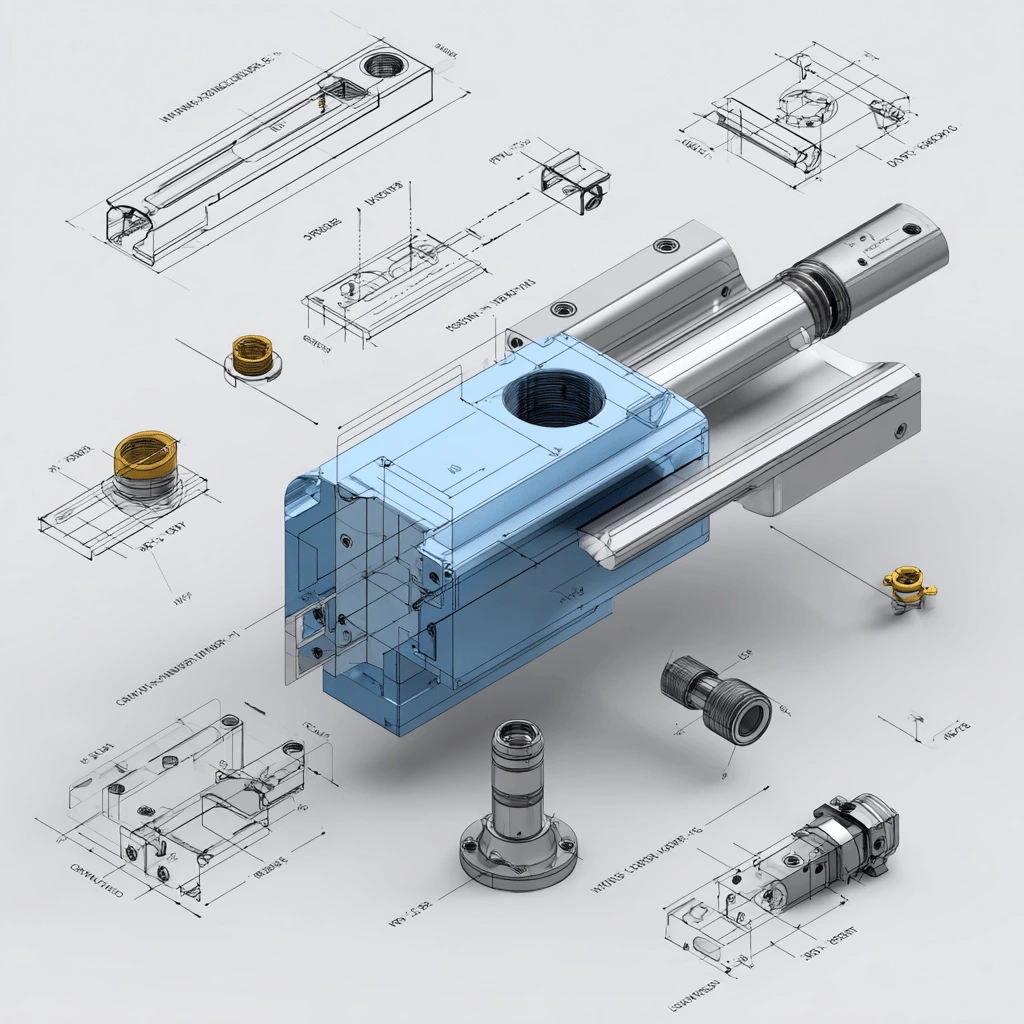

Fixture Design

Tool Design

CAD/CAM Services

Process Planning

Prototyping

Design Validation

Rapid Prototyping Services

Component Types Commonly Prototyped

DFM (Design for Manufacturability) Support

We don’t just machine your part — we help you build it smarter. Our team reviews part geometry, tolerance stacking, and tooling needs to help reduce machining time, material waste, and downstream finishing. Many clients rely on us to:

Recommend tolerances that meet performance without increasing cost

Improve fixturing approach to reduce setups

Suggest material changes or cut optimizations

Guide conversion from casting to billet or vice versa

The earlier you involve us in your project, the more time and cost savings we can unlock.

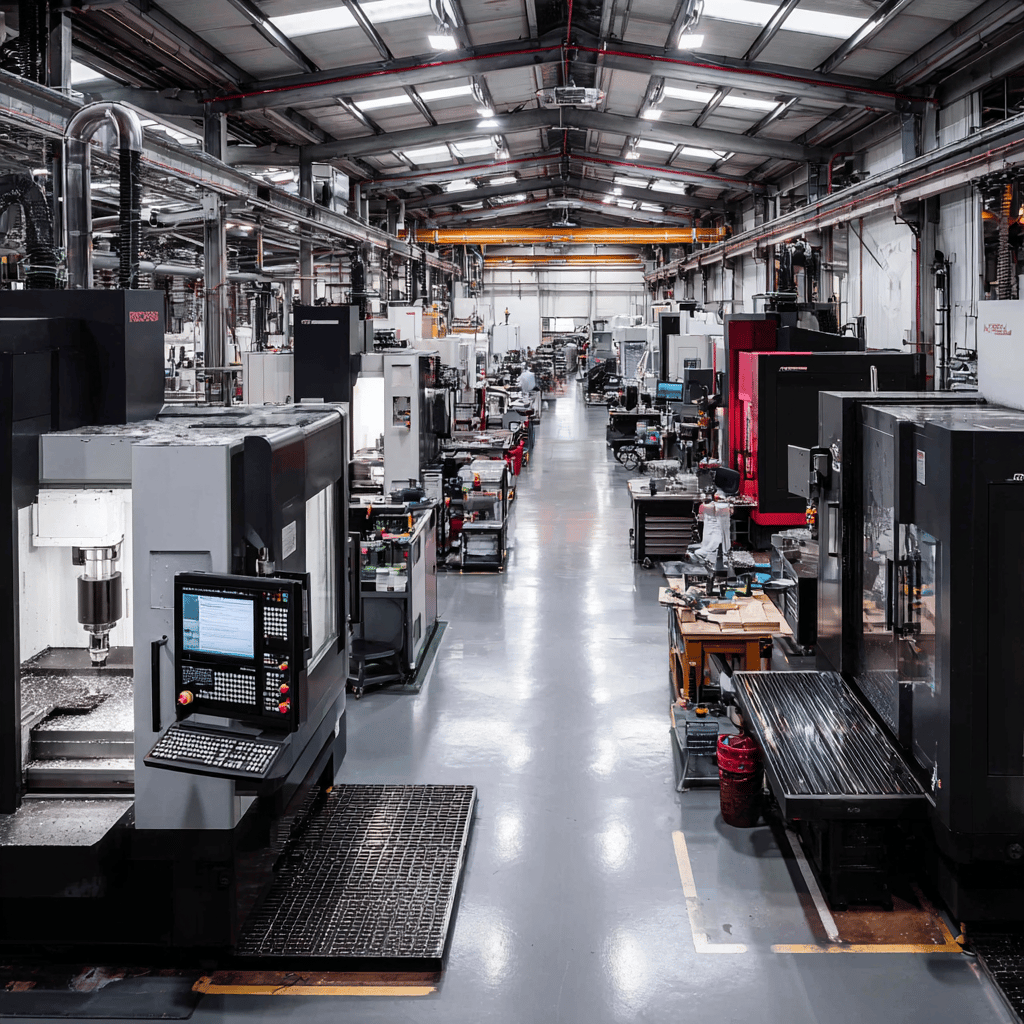

Integrated Workflow: Engineering to Production

Because we engineer and machine under one roof, there’s no delay between design approval and spindle start. This results in:

From paper sketch to fully inspected component — we handle it all.

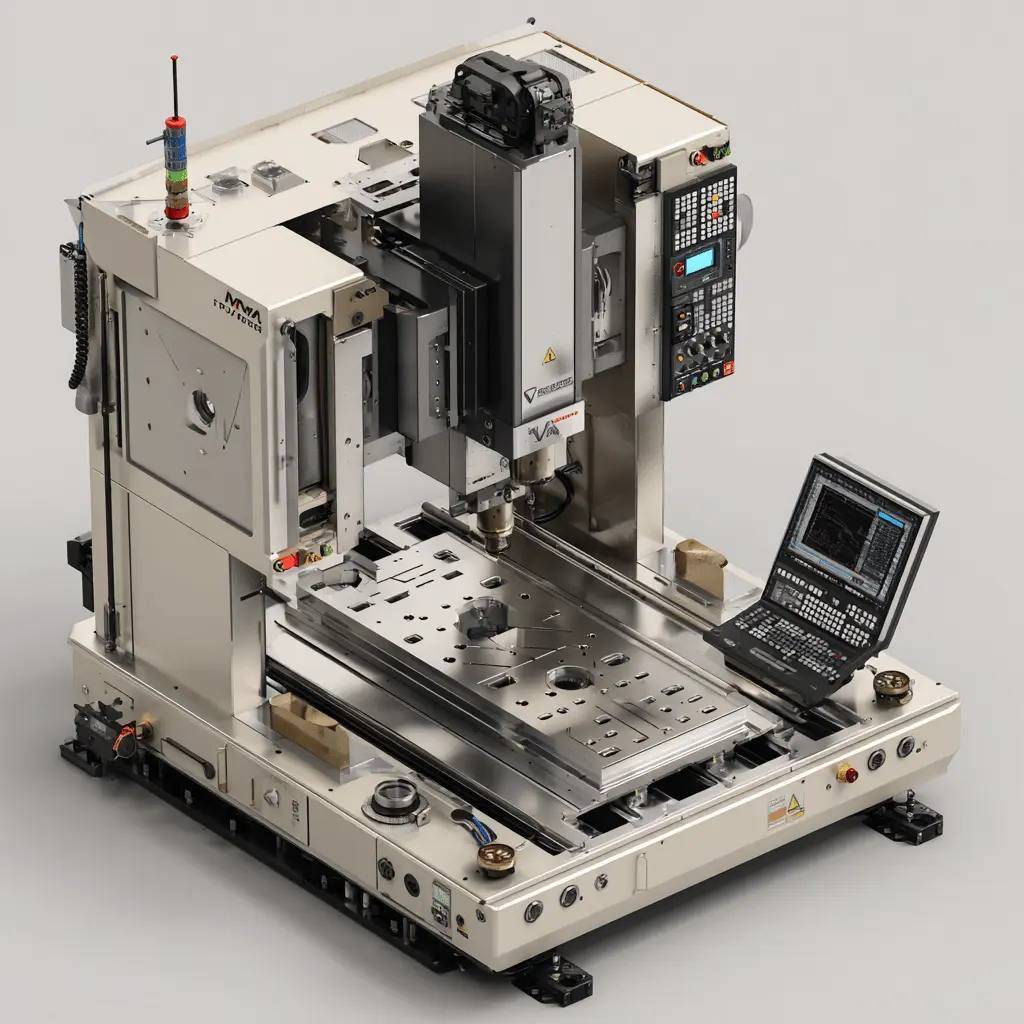

Certifications & Equipment

All engineering and prototyping work is backed by our ISO 9001:2015-certified processes, ensuring quality and traceability at every step.

Why Choose Paramount for Engineering & Prototyping?

We don’t just make your part — we make it better.