Custom build sheets

Precision Assembly & Functional Testing Services

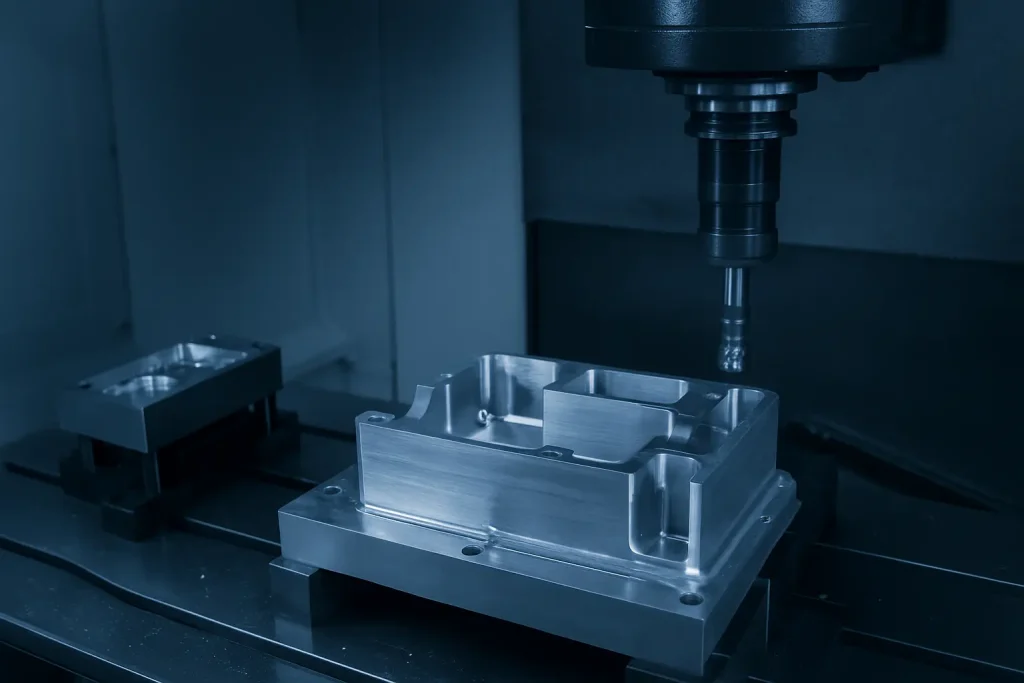

At Paramount Industrial, we go beyond machining by offering in-house mechanical assembly and precision testing services for customers who need ready-to-use components and subassemblies. By combining high-tolerance CNC machining with detailed final assembly and inspection, we help you streamline your supply chain, reduce handling and shipping risks, and improve quality at every step. From pump housings to engine brackets, we build assemblies that are fit-for-function, verified to spec, and production-ready.

Contact Us

📋 Documentation & Traceability

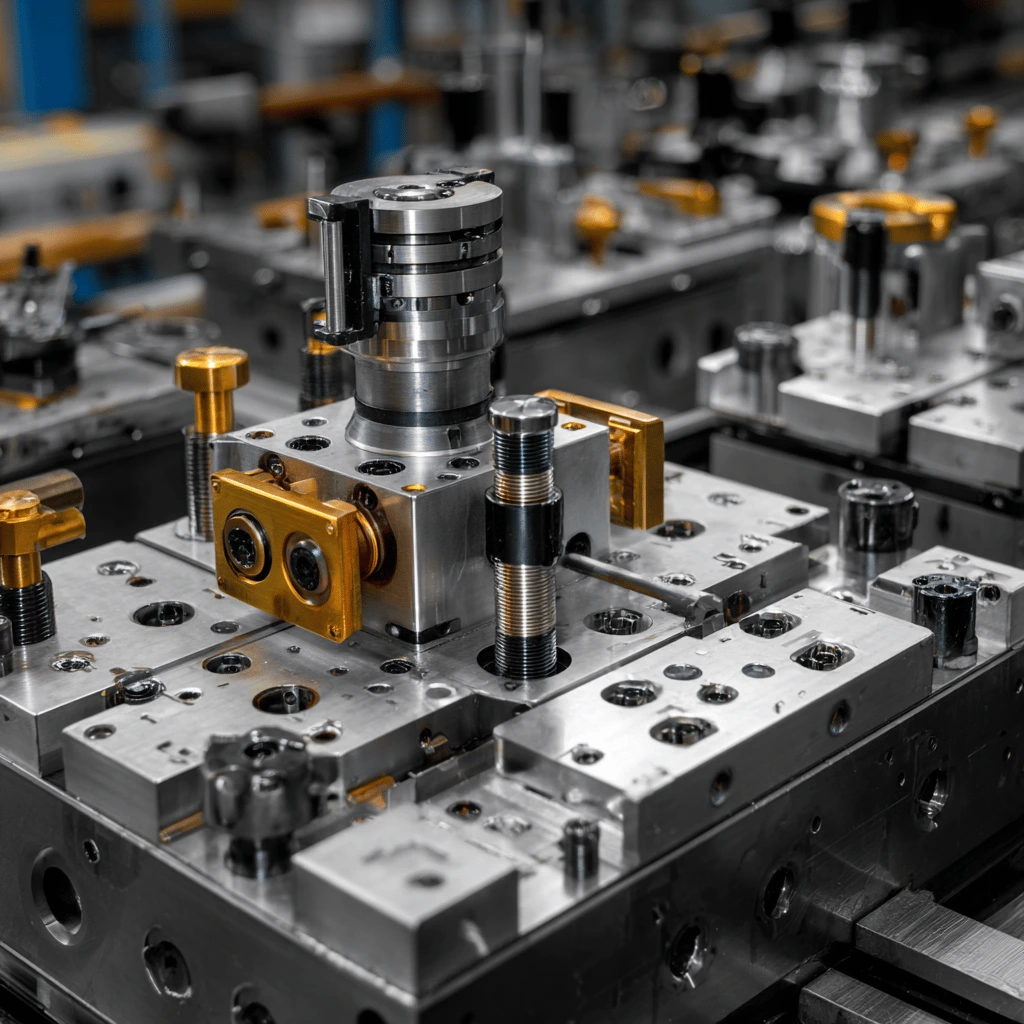

Whether you supply the full BOM or we source the subcomponents, our team handles the final build and quality checks under one roof.

Our Assembly Services

Fully Machined. Fully Assembled. Ready to Install. We provide mechanical assembly and component integration for a variety of machined parts, castings, and engineered systems.

🔧 Mechanical Assembly

🔩 Part Finishing & Prep

Component Types Commonly Assembled

Each assembly is processed through climate-controlled machining and grinding departments before moving into final build and testing — minimizing thermal distortion and ensuring dimensional accuracy.

Functional Testing Capabilities

Every part must perform — so we don’t ship it unless it does. We offer tailored inspection and functional test procedures based on customer requirements, part function, and end use.

Testing Services Include:

All inspection is performed in our ISO 9001:2015-certified facility with full documentation available.

Why Choose Paramount for Assembly & Testing?

Integrated Machining + Assembly

Our machining tolerances of ±0.0005” and grinding tolerances of ±0.0006” are preserved throughout final build and testing, giving you complete control from billet to box. Because we machine, inspect, and assemble on-site, you benefit from:

Certifications & Shop Capabilities

All assembly and testing services operate under our company-wide ISO certification and lean production principles.

Let’s Build It — Together

If you’re looking for a machining partner who can deliver a complete part — built, inspected, and tested — Paramount Industrial is ready.