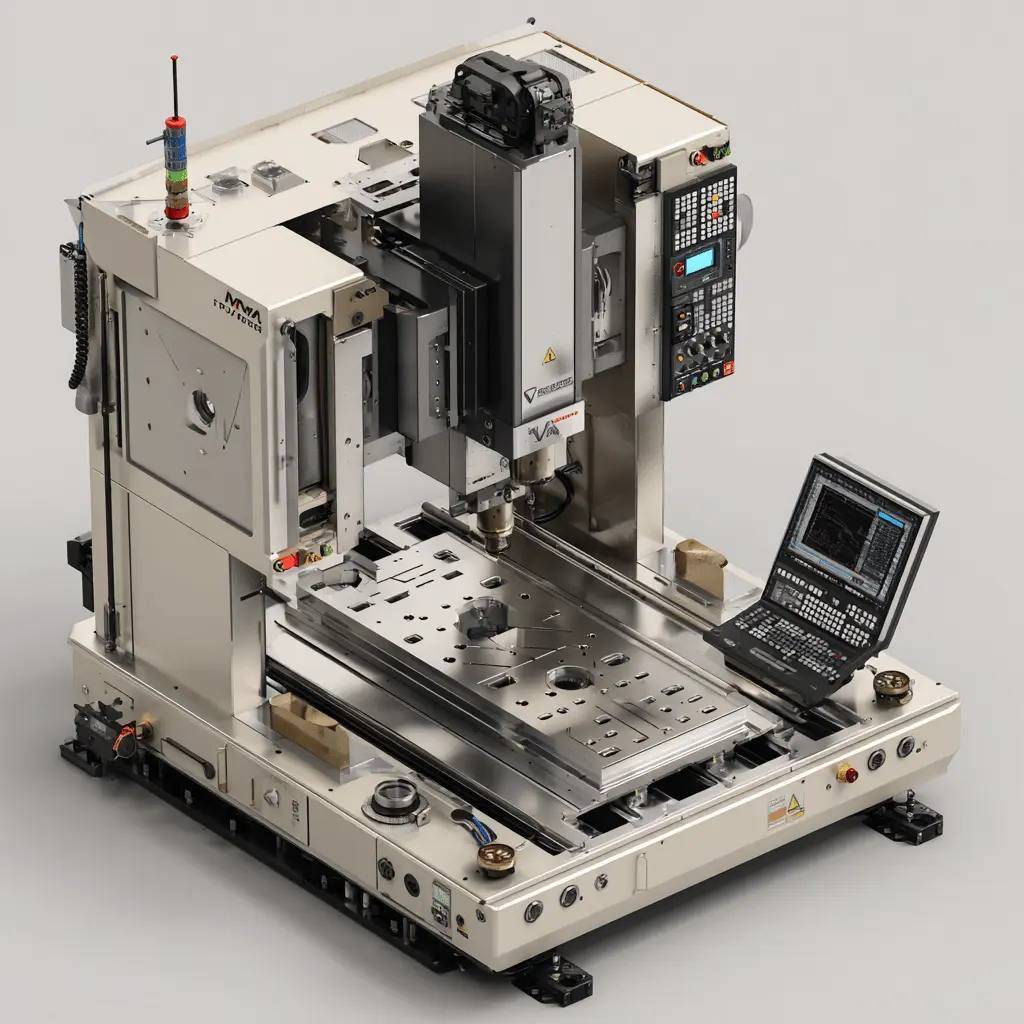

Dual-Pallet 630mm & 800mm Horizontal Mills

Where Performance Meets Precision

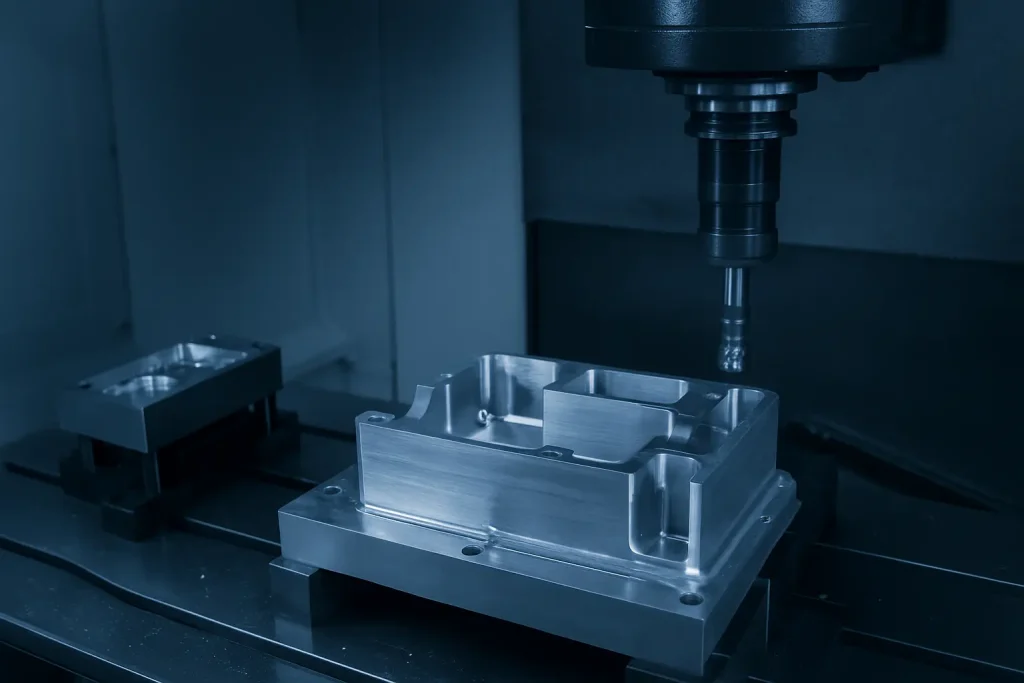

Precision CNC Machining Services

At Paramount Industrial, CNC machining is more than a process — it’s our foundation. From simple brackets to complex powertrain housings, we specialize in high-precision, low to mid-volume CNC machining of aluminum, iron, and specialty alloy components. With advanced multi-axis equipment, CAD/CAM engineering, and over 40 years of manufacturing experience, we deliver exceptional part quality with tight tolerance control, quick changeover capability, and on-time delivery — without excuse.

Machining Capabilities at a Glance

Capability

Details

Machine Types

Horizontal & Vertical CNC Mills, Lathes, Turning Centers

Axes

3-Axis & 4-Axis Machining

Tolerances

±0.0005” per linear foot

Production Volume

1 to 3,000+ parts

Materials

Aluminum, Iron, Steel, Castings, Alloys

Facility

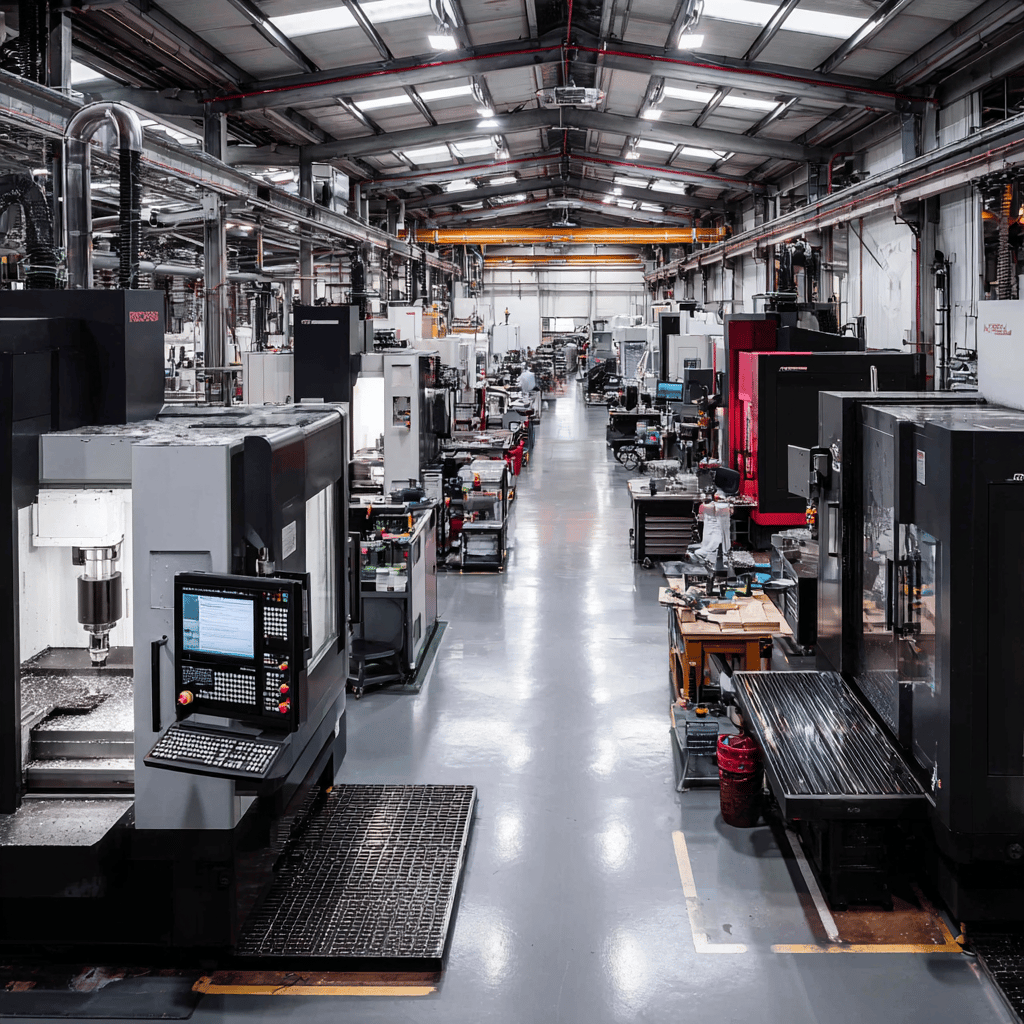

35,000 sq. ft., climate-controlled

Our CNC Machinery Lineup

Paramount is equipped with state-of-the-art CNC equipment to ensure flexibility, reliability, and process repeatability.

Horizontal Machining Centers

Horizontal Machining CentersMachines:

Machines:

CNC Turning Centers & Lathes

Component Types We Machine

We machine a wide range of automotive, industrial, and engineered components, including but not limited to:

Housings & Structures:

Engine & Drivetrain:

Support Components:

Note: All parts are machined to customer specs or jointly developed through our in-house engineering.

Our team selects tooling and speeds/feeds based on material behavior to achieve consistent finishes and dimensional accuracy.

Material Expertise

We machine a wide range of metals and alloys:

Every job begins with intelligent process planning — ensuring that every setup, toolpath, and cut is optimized for quality and efficiency.

Engineering-Driven CNC Machining

Our CNC capabilities are tightly integrated with our in-house engineering and CAD/CAM systems, enabling:

Quality Assurance & Process Control

We integrate real-time inspection into every CNC machining process. Our metrology lab includes:

Our quality program is ISO 9001:2015 certified and driven by lean principles, continuous training, and rigorous inspections at every stage.

Facility Advantages

Get a Quote or Consultation

Ready to machine your part? Whether you’re a Tier 1 automotive supplier or a custom equipment builder, our CNC team is ready to support your design, tolerance, and production needs.

Contact Us